Secant piled walls are constructed by overlapping bored piles to form a continuous wall, often alternating unreinforced “female” piles with reinforced “male” piles. This produces both structural capacity and a watertight barrier. They are used where excavation support must also prevent groundwater ingress, such as in basements, shafts and deep excavations in variable ground.

Basic Technique

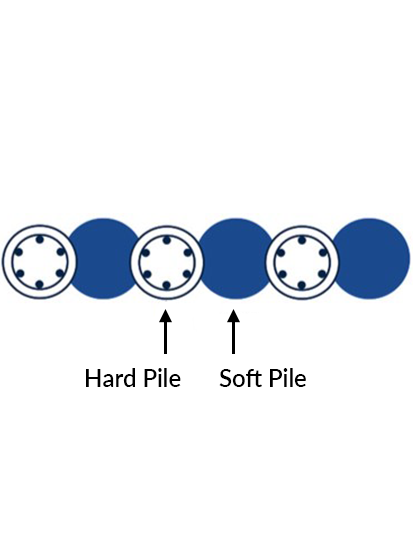

Primary (or Female) piles are installed first. Once the Primary piles have gained sufficient strength, Secondary (Male) piles are constructed in between them and cutting into the Primary piles. The installation sequence is determined by ground conditions but is normally on a ‘hit and miss’ 2 or 3 piles basis. After a sufficient initial curing period (2-4 days) and once each alternate pile is formed, the reinforced ‘male’ piles are installed. Pile overlap (cut) typically ranges from 75mm to 100mm. Primary piles are usually un-reinforced. Secondary piles can be rock-socketed for additional loading requirements and are usually reinforced with full-length steel-reinforcement cages or, less commonly, with steel sections. The secant between hard and soft piles ensures that water seepage is minimised and wash-out of ‘fines’ is prevented. The inter-locking secant wall is not watertight; however water flow is considerably reduced.

After construction, the top section of the piles are broken down and usually incorporated into a reinforced concrete capping-beam. Similar pile sizes and retained heights to contiguous piling can be offered.

Cased Secant Piling

The CSP system has been developed to combine the more cost-effective CFA technique with temporary casings that are more traditionally associated with rotary bored piling methods.

The CSP system generally has the following advantages:

- Better tolerance than an un-cased CFA secant wall.

- Better ultimate appearance and reduced ‘overbreak’ than an un-cased CFA secant wall.

- Speedier operation than the more traditional ‘kelly / casing’ rotary bored pile method.

- Reduced risk of ‘flighting’ in poor soils than a standard CFA system.

- As a cased system, it reduces the risk of distress to adjacent structures in certain soils like sands or gravels.

In general terms, whilst the CSP process does have limitations with respect to diameter and depth, it will generally give a more assured product in terms of vertical tolerance and aesthetics.